We Are Akshar Engineering

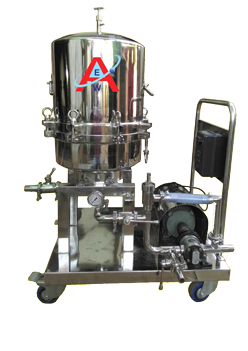

Works established in 1996, are one of the precursor firms influential in manufacturing, supplying, exporting wide array of Pharmaceuticals Machinery. Our offered types of products include Sparkler Filter Press, OIL Filter Press and Filter Press Filtration Machine. We have attained wide acceptance in the market for implementing progressive technology for fabrication of these machines. These products are much appreciated in the market for sturdiness, precise finishing and superior functionality traits. With the fabrication being done by using quality-tested raw materials, these machines are available with us in wide preferences.

Our Strategic Sustainability

With the aim of employing maximum precision functionality in our products, we have developed high-end infrastructure system. With the potent use of machinery in advanced manufacturing facility, we are able to fabricate different types of machines thus serving diversified demands of customers. Our products range fulfills the every parameters of quality for gaining maximum output of them. Moreover, we make the supply of these machines to customers in durable packaging at nominal price range. We utilize a team of hard working personnel who ensures the highest level of quality production. Owing to these attributes, we cater to variegated needs of clients globally with uttermost perfection.

Our company has embarked on this domain with great achievements under the guidance of Mr. Vishal Panchal. The prime focus on delivering quality and ensuring ethics at all levels of client dealing has earned us a respectable global customer base.